Forward Curved Blower

Product Details:

Product Description

Backed by an advanced and sound infrastructural facility, we are able to provide our clients with a comprehensive assortment of Forward Curved Blower. These blowers are manufactured using high quality raw material with the international quality parameters. Further, our entire range is tested on well-defined parameters to ensure its flawlessness at clients' premises. In addition to this, we offer these products to our clients at market leading prices.

Features:

Long functional life

Sturdiness

Anti Corrosive

Specifications:

- It can handle large volumes of air with at low pressure.

- It operates at low speeds

- Forward Curved Blowers provide smooth, quiet operation for low pressure, high volume applications.

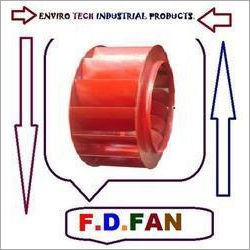

Types of Forward Curved Blowers:

Single Inlet Single Width (SISW)

Double Inlet Double Width (DIDW)

Application:

- It has extensive use in Heating, Ventilation & Air-Conditioning systems.

Model:

FAFC-SF 450 to FAFC-SF 1000

Capacity:

Capacity ranges from 2900 CFM to 39000 CFM

Pressure:

Total Pressure Ranges upto 150 mm wg

Housing:

Casing is constructed in GI Sheets to increase the life against rusting. Sides of fans are pittusburg locked with pittsburg lock formers.

Impeller:

Impellers have forward curved blades which are manufactured with extensive pression to enhance the performance in terms of efficiency & noise levels

Impellers are dynamically balanced as per standards.

Supporting Frames:

To provide the rigidity & stability to fan side frames are manufactured from Alngle Section with welding. Surface is finished with either of enamel paint, epoxy paint or powder coating.

Shafts (Grinded):

Shafts are manufactured from EN-8 carbon steel which is machined & grinded to allowable tollerences. Keyways are cut as per standards

After assembly shafts are coated with Laquer or varnish.

Bearings:

Bearing used in Fan Air Fans are deep groove or spherical roller type of international standard which have eccentric locking collars

These bearing are self-aligned and pre- lubricated and are maintenance free

Inlet Cones:

Inlet cones are made up of FRP

Forward Curved Blowers / Didw Fans