Dwyer A3000-100MM Photohelic Pressure Switch Gauge Range 0-100 mm w.c

Product Details:

- Weight 4 lb (1.81 kg) Kilograms (kg)

- Size 4" (101.6 mm) dial face, 5" (127 mm) O.D. x 8-1/4" (209.55 mm)

- Usage Air and non-combustible, compatible gases

- Scale Range 0-100 mm w.c

- Accuracy 2% of FS at 70F (21.1C) %

- Click to View more

Dwyer A3000-100MM Photohelic Pressure Switch Gauge Range 0-100 mm w.c Price And Quantity

- 1 Piece

- 40000 INR/Piece

Dwyer A3000-100MM Photohelic Pressure Switch Gauge Range 0-100 mm w.c Product Specifications

- 4 lb (1.81 kg) Kilograms (kg)

- 4" (101.6 mm) dial face, 5" (127 mm) O.D. x 8-1/4" (209.55 mm)

- Air and non-combustible, compatible gases

- 2% of FS at 70F (21.1C) %

- 0-100 mm w.c

Dwyer A3000-100MM Photohelic Pressure Switch Gauge Range 0-100 mm w.c Trade Information

- Cash Against Delivery (CAD) Cash on Delivery (COD) Telegraphic Transfer (T/T) Paypal Cash in Advance (CID) Cheque Cash Advance (CA)

- Sample costs shipping and taxes has to be paid by the buyer

- EXTRA

- Australia South America Middle East Western Europe Asia Central America Eastern Europe North America Africa

- Dadra and Nagar Haveli Chandigarh Himachal Pradesh Nagaland Uttarakhand Daman and Diu South India North India East India Andaman and Nicobar Islands Andhra Pradesh Assam Arunachal Pradesh Bihar Delhi Gujarat Goa Haryana Jammu and Kashmir Jharkhand Karnataka Madhya Pradesh Maharashtra Mizoram Meghalaya Manipur Odisha Punjab Pondicherry Rajasthan Sikkim Tamil Nadu Telangana Tripura West Bengal Lakshadweep Uttar Pradesh Kerala Central India West India Chhattisgarh All India

- YAS

Product Description

Dwyer A3000-100MM Photohelic Pressure Switch Gauge Range 0-100 mm w.c

Dwyer, A3000-100MM-240VAC A3000 Photohelic Switch/Gage

Range: 0-100 mm w.c., Power: 240 VAC

Brand # Dwyer Part # A3000-100MM-240VAC Model # A3000 Photohelic

Condition Brand New

Dwyer, A3000-100MM-240VAC, A3000 Photohelic 240 VAC Pressure Switch/Gage, Range 0-100 mm w.c.

3-in-1 Indicating Gage, Lo-limit and Hi-limit Control

Photohelic Switch/Gage Function as Versatile, Highly Repeatable Pressure Switches Combined with a Precise Pressure Gage Employing the time-proven Magnehelic gage design. The Photohelic switch/gage measures and controls positive, negative or differential pressures of air and compatible gases. Standard models are rated to 25 psig (1.7 bar) with options to 35 (2.4) or 80 (5.5 bar) psig. Single pressure 36000S models measure to 6000 psig (413 bar) with a 9000 psig (620 bar) rating. Two phototransistor actuated, DPDT relays are included for low/high limit control. Easy to adjust set point indicators are controlled by knobs located on the gage face. Individual set point deadband is one pointer width - less than 1% of full scale. Set points can be interlocked to provide variable deadband - ideal for control of fans, dampers, etc. Gage reading is continuous and unaffected by switch operation, even during loss of electrical power.

Photohelic Sensing - How It Works

In typical applications, these Dwyer Switch/Gages control between high and low pressure set points. When pressure changes, reaching either set point pressure, the infrared light to the limiting phototransistor is cut off by the helix-driven light shutter. The resulting phototransistor signal is electronically amplified to actuate its DPDT slave relay and switching occurs. Dead band between make and break is 1% of full scale or less - just enough to assure positive, chatter-free operation.

Relay-Transformer Features

A plastic housing protects all electronic components. Solid-state and integrated circuit electronics are on glass-epoxy printed circuit boards and self-extinguishing terminal boards.

Applications - Photohelic Switch/Gage

In both Series of Pressure Switch/Gages, you get the convenience of a visual indication plus high-low limit switching. For both OEM and in-plant applications, the Photohelic switch/gage is used to control pressures in air conditioning systems, clean rooms, fluidic and pneumatic control systems, materials handling equipment, alarm or control fume exhaust systems, control pressure in air structures, and monitor respiratory and blood pressures.

Standard Model

Two phototransistor-actuated circuits and two DPDT relays permit both high and low alarms or limit controls. Relays are de-energized when gage pointer is to the left of respective set points; relays are energized as pointer passes to the right of set points. Loss of electrical power or loss of pressure provide "fail safe" protection.

High and Low Latching Circuits

Dwyer Photohelic Switch/Gage can be wired for high-latching, low-latching, or combination high-low latching circuits. That is, the equipment will hold in these respective positions once activated and until manually reset. This can be particularly useful for alarm and signal applications where control is accomplished by another Photohelic switch/gage or other means. Complete wiring and operational instructions are included. Where manual reset is required a dry circuit push button such as Dwyer Part A-601 should be used.

Features

Bezel and front cover(with set point knobs and zero adjustment screw) removed to expose Photohelic gage set point mechanism. Cover is clear polycarbonate plastic

Gage pointer and light shutter are mounted on helix and balancing counterweight. Shutter passes through slot in optical limit switch to expose phototransistors to integral infrared light source or mask them depending on applied pressure

Light shield effectively protects phototransistors from strong outside light sources yet allows free pointer movement. It also gives interior a clean "finished" look

Optical limit switches are used for reliability and long service life. Attached directly to set pointers, they are individually aligned to assure precise switching accuracy

Semi-Flexible drive shaft connects to set point knobs

Zero adjustment screw connects to screw in cover to adjust zero pressure reading

Plastic enclosure protects electronic components and electrical connections

Polycarbonate connection or terminal board is self-extinguishing

Glass-epoxy printed circuit boards for durability and performance

Load relays are DPDT with latching feature for maximum application versatility

Electronics are designed to operate on 50 Hz, 240 Volt current with 10% over or under voltage.

Switch set pointers show switch settings at all times

Spring loaded friction clutch prevents operator damage of set point mechanism

Gage Specifications

Service :Air and non-combustible, compatible gases

Range :0-100 mm w.c.

Accuracy :±2% of FS at 70°F (21.1°C)

Pressure Limits :-20" Hg. to 25 psig (-0.677 to 1.72 bar)

Temperature Limits :20 to 120°F. (-6.67 to 48.9°C)

Process Connections :1/8" female NPT

Size :4" (101.6 mm) dial face, 5" (127 mm)

O.D. x 8-1/4" (209.55 mm)

Weight :4 lb (1.81 kg)

Switch Specifications

Switch Type :Each setpoint has 2 Form C relays (DPDT)

Repeatability :±1% of FS

Electrical Rating :10A @ 240 VAC

Electrical Connections :Screw terminals. Use 167°F (75°C) copper conductors only

Power Requirements :240 VAC, 50 Hz

Mounting Orientation :Diaphragm in vertical position

Set Point Adjustment :Adjustable knobs on face

Agency Approvals :CE, CSA, UL

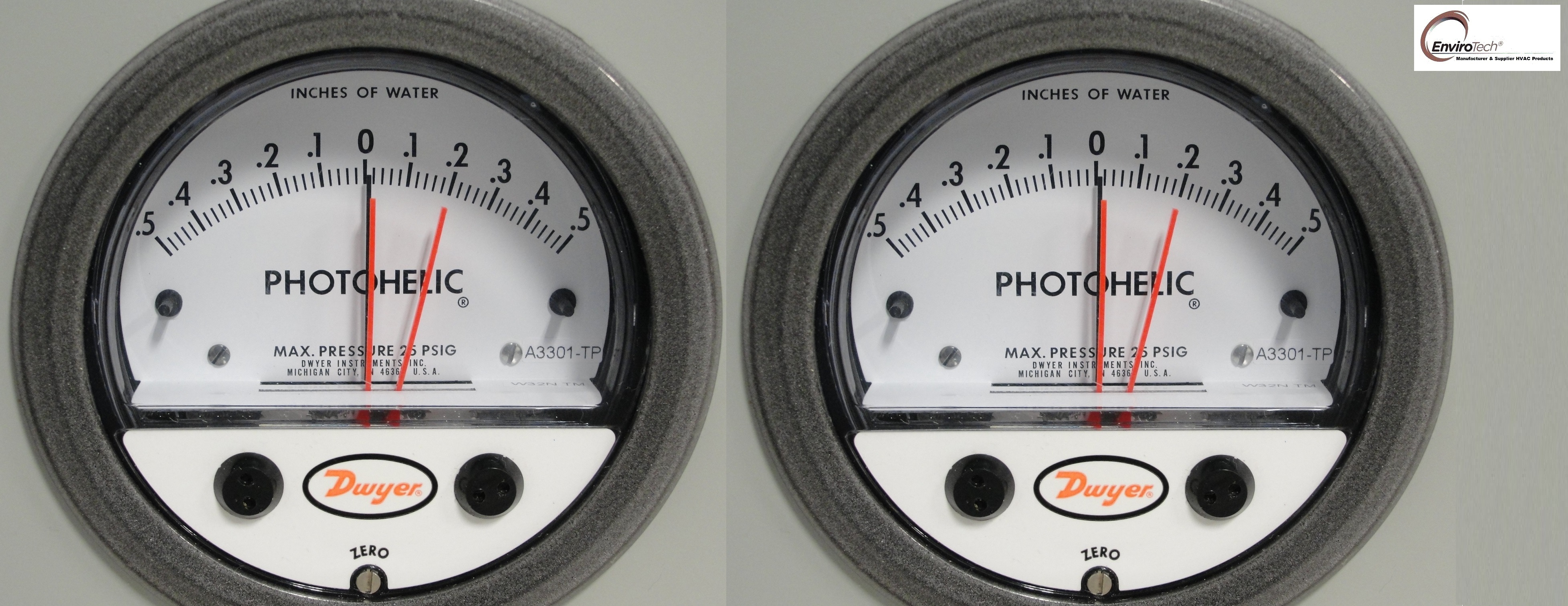

Dwyer A3300-0 Photohelic Pressure Switch Gauge Range .25-0-.25 Inch w.c

Price: 40000 INR/Piece

- 50

- 100

- 200

- 250

- 500

- 1000+